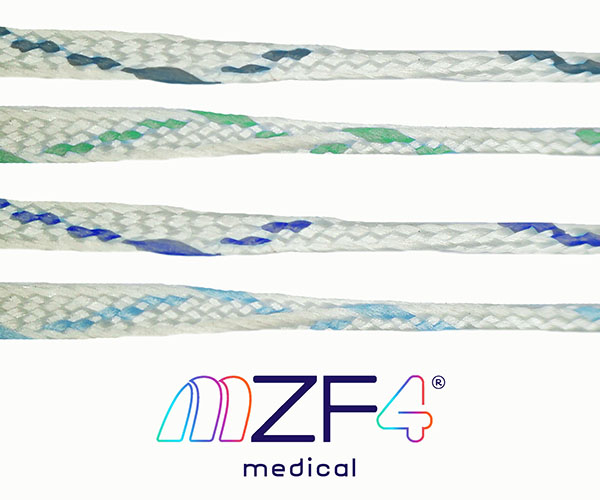

Variable-Geometry Tapes

Innovation in the Round2Tape2Round UHMWPE Precut & Tipped Suture for Sports Medicine

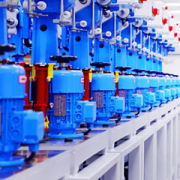

After two years of research, MZF4 Medical R&D and Innovation team has developed a new manufacturing process to produce variable-geometry tapes on a large scale. This breakthrough aims to meet the high demand in the Sports Medicine sector, enabling high-volume production and shorter delivery time to customer orders.

With this innovative and fully automated process, we are now able to:

• Produce up to 100,000 units per braiding head per year

• Perform setup of the three parts (round/flat/round) independently of their respective masses

• Ensure greater dimensional stability (round part diameter, tape width/thickness, and length of the three parts)

• Guarantee consistency in PPI (plates per inch)

• Precise transition from tape to round sections of the sutures

This new process, already in operation, is being patented by MZF4 Medical and showcases our commitment to the “no trade-off company” philosophy, where speed and customization go hand in hand.